Intelligent Cloud Based System to promote Healthy and Safe Smart Industries

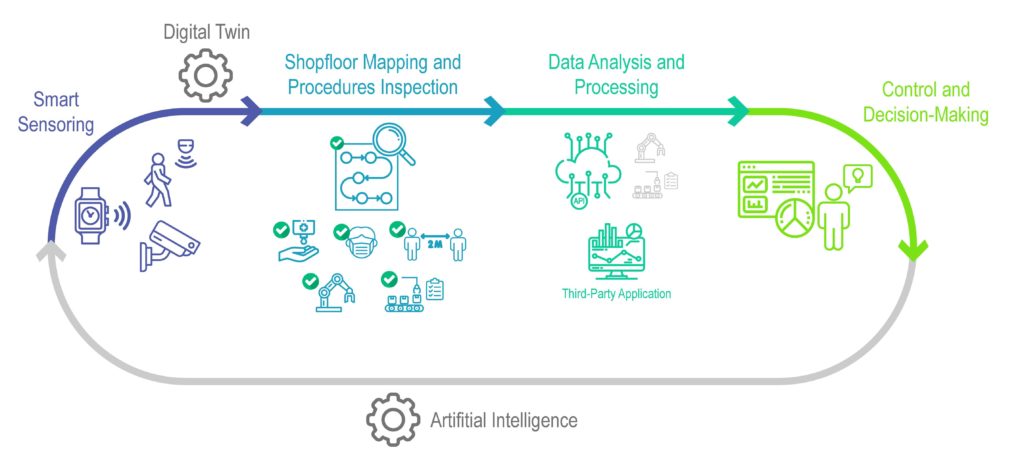

The experiment aims to validate the integration of smart devices (camera and watches), advanced data processing algorithms and intuitive dashboards (actuated locally and remotely) , i.e. a Cyber-Physical and embedded System (CPES) to monitor, feedback and improve two conflicting needs in manufacturing SMEs: the full respect of health and safety rules strengthen by COVID (personnel equipment use, safe distance, hygienic routines, etc.) and the respect of optimized operators and materials movements, and operational and quality procedures.

| Partner | Role | Expertise |

|---|---|---|

| ERISING | Experiment leader | Erising (Efficiencyrising, Lda) is a company founded by two mechanical engineers trained at Instituto Superior Técnico. Erising aims to promote customer talent and value by looking for waste and inefficiencies and transforming them into opportunities for improvement. |

| MUVU Technologies | Technology provider | MUVU developed a software focused on transforming meaningful data from machines into powerful knowledge to increase the levels of decision making, performance and compliance in every industry. |

| IMAN NOTRE HUB | DIH | The mission of the Digital Innovation Hub for Customer-Driven Manufacturing at Norte (iManNorte Hub) is to foster the digital transformation of manufacturing companies of the Northern Region of Portugal (Norte) and to nurture the respective innovation ecosystem. |

The experiment aims to validate the integration of smart devices (camera and watches), advanced data processing algorithms and intuitive dashboards (actuated locally and remotely) , i.e. a Cyber-Physical and embedded System (CPES) to monitor, feedback and improve two conflicting needs in manufacturing SMEs: the full respect of health and safety rules strengthen by COVID (personnel equipment use, safe distance, hygienic routines, etc.) and the respect of optimized operators and materials movements, and operational and quality procedures.

- The proposed CPES experiment in industrial environment will allow real time alarmistic signals to the operators when deviations occur and additionally remote supervision and intelligent assessment by identifying critical points and procedures (highly required in the COVID context that demands to reduce the number of elements in the shop-floor).

- This experiment will have a high impact on the health and safety rules fulfilment by SME (lowering COVID spread risk), and guaranteeing an high operational performance.