Increased productivity in olive processing by implementing CPS and image recognition

Olive sector is a relevant agriculture sector in Spain, as shown by its leading role worldwide with a production worldwide of 38%, while Italy and Greece have 20% and 13% respectively. With over 400 thousand olive growers, the sector requires a deeper professionalisation a keep competitive against other Mediterranean countries where labour cost is cheaper, as Turkey or Cypress.

The Application Experiment proposed tries to implement CPS know-how and Image Recognition technology on an olive farming cooperative for increasing its productivity on olive processing stages.

| Partner | Expertise | Role |

|---|---|---|

| UPV | HUB-4-MANUVAL DIH coordinator. MES development and customization. IoT and M2M protocol expertise. | Technical partner |

| MULTISCAN | Design and supply of X-ray technology systems for safety and conformity applications in the food industry for sorting and grading | End-User |

| ITI | HUB-4-MANUVAL DIH partner. Hybrid architectures edge-cloud to deploy real time optimization processes. Artificial Intelligence applied to Cyber Physical Systems for self learning. Big Data Analytics. | Technical partner |

Problem/Business Case description

Olive processing is a challenging task, requiring the quick grade and sort of olives for its classification according to different purposes as stages: raw vs processed olives, or olive oil vs cooked/pitted olives.

MULTISCAN is a food tooling manufacturing company with know-how on applying state-of-the-art machine vision technologies along with innovative product transport systems to achieve optimum sorting. Multiscan provides unique solutions for the fresh fruit and vegetables market, sorting and grading by color, size and quality, becoming the real specialist in product up to 55 mm in diameter. Moreover, Multiscan designs and supplies X-ray technology systems for safety and conformity applications in the food industry.

MULTISCAN expertise is focused on tooling for grading and sorting Olives, Cherries or Cherry Tomatoes, being olives its main relevant business.

MULTISCAN increase the added-value of its products through the integration of the machines with MES systems that will demonstrate the production benefits of using MULTISCAN machine in their customers (cooperatives and large customers).

The objective of the application is to transfer HUB-4-MANUVAL DIH know-how on robotics and MES systems (UPV), and Edge/Cloud architectures, Artificial Intelligence and Big Data Analytics (ITI). That expertise will be integrated on MULTISCAN machines and software through the use of standard industrial M2M communication protocols, as OPC UA, to develop high-value customised processes on the olive manipulation. For this purpose, an olive farming cooperative will provide the facilities and will validate the developed proposal.

AE description

HUB4MANUVAL Digital Innovation Hub expertise on Robotics, CPS/IoT and Artificial Intelligence (AI) by Valencian manufacturing SMEs and MidCaps will prove valuable for the business case. The HUB will support manufacturing companies in order to be more competitive, prioritizing SMEs in the manufacturing sectors of relevance at Regional Level. The previous know-how on Agriculture, hunting and forestry sector with projects such as “CPS based on vision systems“ (https://bit.ly/2FPmEaz) emphasis the value proposition that UPV and ITI, as coordinator and partner of the DIH, can bring to MULTISCAN to solve the problem in scope.

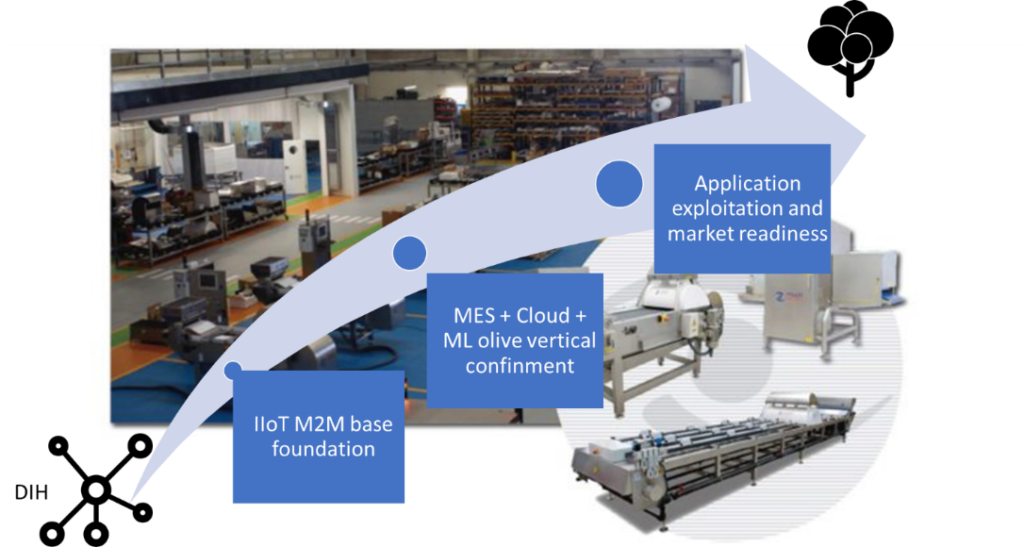

The experiment will be phased in three stages:

Phase 1: IIoT M2M base foundation (M01-M12).

This phase covers the definition of the application vision (scope on olive processes, KPIs and success indicators). The Technical Architecture will be focused on MULTISCAN machine and embedded software integration with M2M OPC UA protocol. The architecture defined will be based on Edge/Cloud requirements and Architecture definitions done at this stage. An Exploratory Data Analysis for predictive maintenance of MULTISCAN Machines will be done.

Finally, this stage will commit a Technical Base Development.

Phase 2: MES olive vertical development & Cloud configuration board & Predictive maintenance (M10-M24).

This phase will design the MES functional alignment to Olive Vertical requirements and will develop a customised vertical module on the MES system.

Therefore, the MES integration onto IIoT M2M base foundation will be done. The solution will be based on cloud application for controlling all multiscan machines.

Finally, Predictive maintenance techniques based on Multivariant analysis and Machine learning techniques will be developed and applied to support the predictive maintenance.

Phase 3: Application exploitation and market readiness (M22-M36).

This stage covers the deployment of integrated MesView-Multiscan embedded system with cloud control with predictive maintenance module vertical solution on an olive farming cooperative. The solution will be evaluated into the cooperative so minor software adaptations could be needed.

This stage finishes with the packetization of the solution and general market readiness.

The CPS software solution that HUB-4-MANUVAL will transfer is based of production readiness software based on:

- vf-OS – virtual factory Open Operating System – is a project funded by the H2020 Framework Programme of the European Commission under Grant Agreement 723710 (https://www.vf-os.eu/). vf-OS IO Toolkit module provides an extensible opensource solutions supporting a range of industrial M2M protocols such as OPC UA, Modbus, MQTT or CoAP.

- MESView, a proprietary Manufacturing Execution System, which helps improve the performance and control of manufacturing operations.

- The solution shows all your team when and how losses occur, allowing minimize costs and optimizing the Resource performance (machinery, labor, raw materials, energy).

- RADIATUS, a platform to provide to the end-user a BDAaaS (Big Data Analytics as a Service) solution in the Cloud. This platform has been sketched based on two differentiate solutions, one elastic ITI’s Platform as a Service (PaaS), and on top of this PaaS, an end solution is developed as a BDAaaS.