Milling Process Optimization based on AI Driven Dashboards

The application experiment led by SAVVY, a Spanish SME skilled on cloud monitoring and data analytics, will involve IDEKO, a research centre representing Basque Digital Innovation Hub (BDIH), and will apply and validate the developments over AEROMEC, a Spanish aerospace components machining company, in which the milling process of an aeronautic compressor case will be studied.

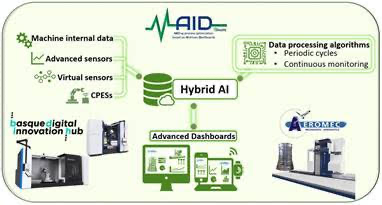

The developed solution will offer currently not accessible information to optimise the cutting process by modifying the process parameters in cases where they can be improved, scheduling the maintenance to maximise the availability of the machine and organising plant production. For that purpose, M-AID will integrate the latest ICT technologies for harvesting the huge quantity of data offered by machines and embedded systems, in which a hybrid artificial intelligence will be used, by combining predictive and prescriptive analysis solutions. In this way, the developed tool will provide support in the decision making of process optimization, predictive maintenance and production planning. The processed information will be combined with advanced dashboards, including wearables, wherein the surveillance and inputs from plant actors will be collected.

| Partner | Role | Expertise |

|---|---|---|

| SAVVY | Technology provider | Experiment leader, Spanish SME skilled on cloud monitoring and data analytics. |

| IDEKO | DIH | Research centre representing Basque Digital Innovation Hub (BDIH). |

| AEROMEC | End-user | Spanish aerospace components machinery company, in which the milling process of an aeronautic compressor case will be studied |